Project PYROLY

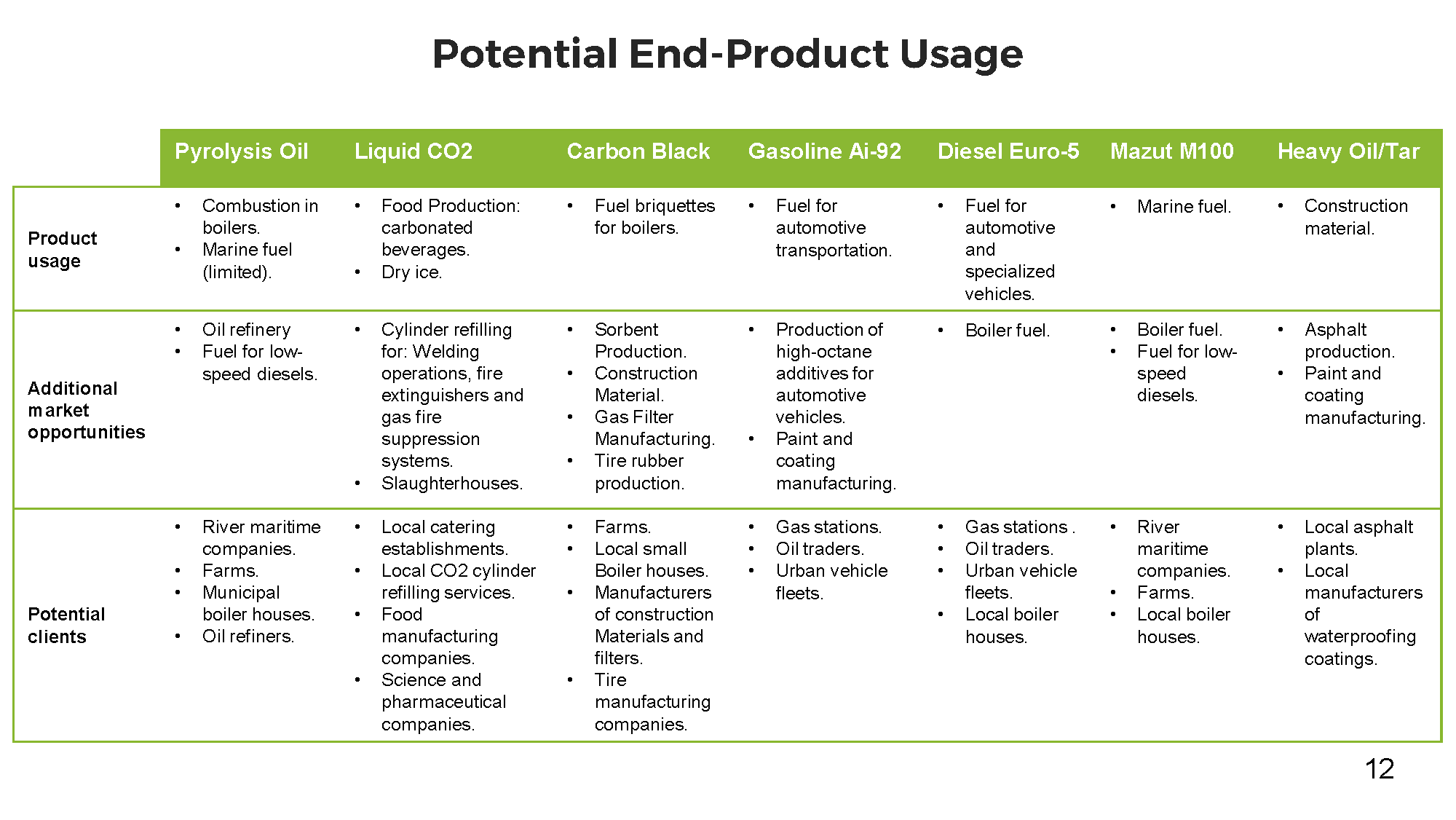

Our solution is the construction of a waste-to-fuel pyrolysis plant in Estonia with an initial processing capacity of 27,000 tons of used tires per year. This waste utilization facility on a 7.73-hectare land will operate with zero CO2 emissions and without generating hazardous residues, making our business completely environmentally friendly. Due to its high utilization efficiency, the plant will be entirely self-sustaining, producing its own electricity and heat while generating revenue from the sale of high-quality end- products such as pyrolysis oil, carbon black, liquid CO2, and more.

Commercial use

This section covers installations, market analysis, and multiple development strategies aimed at preserving and enhancing investment capital amidst the global financial and social crisis. By utilizing products derived from waste disposal, investors can embark on diverse infrastructure projects, enticing both private and public investments. In each operational domain, the presence of self-sufficient fuel or energy inevitably positions it as a frontrunner, given that these components constitute the majority of expenses influencing the ultimate pricing of a product or service.

PYROLY Ocean: Pyrolysis Deployment in the Maritime Industry -

Description of the Technology

As of February 2024, our pyrolysis technology stands out as one-of-a-kind. Our innovative solutions offer completely environmentally friendly waste utilization options on an industrial scale. While others still contend with paying for CO2 quotas in the EU, our clients can capitalize on the absence of toxic emissions from our plants, thereby enhancing their profitability. Furthermore, our solutions are individually tailored for each client to maximize waste utilization efficiency, granting us an edge in achieving energy self-sufficiency while operating the plant, thanks to our high waste conversion efficiency, which reaches up to 97%. Our plants are designed to operate autonomously, and we also offer mobile pyrolysis solutions for both maritime and land applications.

Use waste to fulfill your business ideas successfully

Fuel Trade

Cryptocurrency Mining Plants

Agriculture / Greenhouses

Waste Management

World Waste Problem Solving

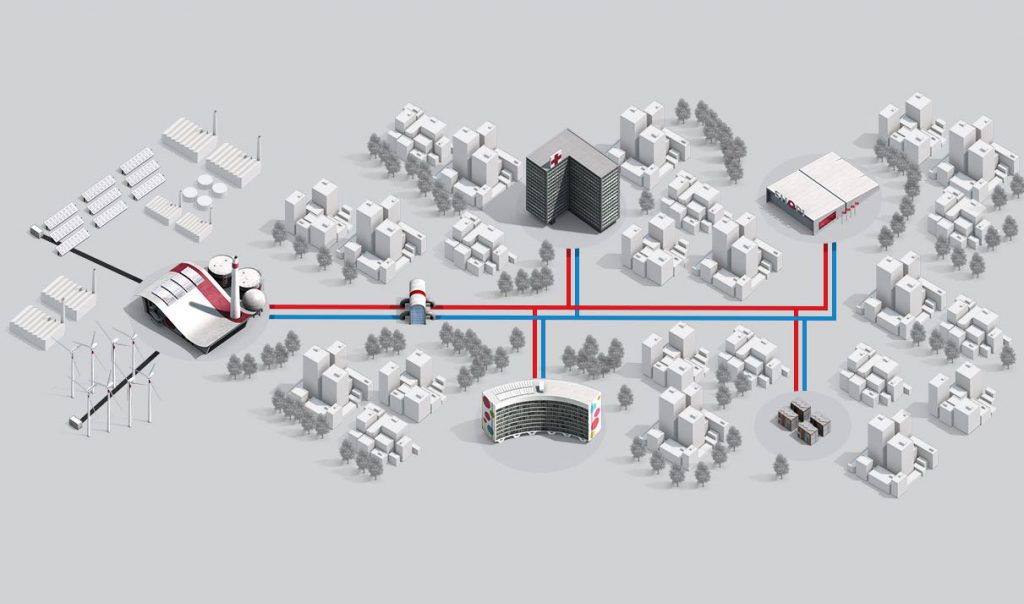

Municipal District Heating

Trash-collecting Ships

Sludge Treatment

Energy Independent Settlements