Technology

COMPLETELY ENVIRONMENTALLY FRIENDLY PYROLYSIS SOLUTIONS FOR MUNICIPAL AND INDUSTRIAL WASTE TREATMENT PURPOSES

To ensure healthy production ecology, the complex employed three filtering systems and linking of harmful substances:

Download our technology presentation

What is pyrolysis?

Pyrolysis is a technological process where raw material is heated in the absence of air, leading to its deep decomposition and the transition of organic components into a gaseous state. This process takes place in a unit made of heat-resistant stainless steel. During pyrolysis, the raw material is transformed into pyrolytic gas, which is then separated into liquid and gaseous phases. These products can be further used as fuel or other materials.

The specifics and volume of the products obtained depend on the type of raw material. For instance, more carbon black and pyrolytic liquid are produced from rubber. The technology also includes the fractionation of pyrolytic liquid, allowing for the isolation of different types of fuel based on its composition.

One of the main advantages of pyrolysis is its eco-friendliness. Firstly, it allows for the recycling of waste, such as plastic and rubber, thereby reducing environmental impact and landfill volumes. Secondly, thanks to the closed process, there are no harmful emissions. Additionally, to ensure extra ecological production, filtration systems are used in the complex, preventing pollutants from entering the atmosphere.

Our, PYROLY solutions

CATALANA OÜ, in collaboration with branches, engineers, and developers from the consortium, has successfully created over 10 sets of equipment for recycling various types of waste, including municipal solid waste, rubber waste, plastic, agricultural waste, and oil industry waste. This long-standing 14-year collaboration has led to the creation of prototype industrial installations, including:

1. PYROLY-EKOPYR “OS”: designed for processing oil sludges and acidic resins.

2. PYROLY-EKOPYR “RP”: adapted for processing rubber, plastic, and polyethylene.

3. PYROLY-EKOPYR “EG”: geared towards processing mixed waste of various kinds.

The PYROLY-EKOPYR system, manufactured by us within the European Union using modern technologies, offers unique advantages in terms of productivity, product output, and price compared to approximately similar equipment produced in other countries.

The specifics and volume of the products obtained depend on the type of raw material. For instance, more carbon black and pyrolytic liquid are produced from rubber. The technology also includes the fractionation of pyrolytic liquid, allowing for the isolation of different types of fuel based on its composition.

One of the main advantages of pyrolysis is its eco-friendliness. Firstly, it allows for the recycling of waste, such as plastic and rubber, thereby reducing environmental impact and landfill volumes. Secondly, thanks to the closed process, there are no harmful emissions. Additionally, to ensure extra ecological production, filtration systems are used in the complex, preventing pollutants from entering the atmosphere.

PYROLY Advantages and Features

- The pyrolysis reactor in the complex allows the recycling of various types of waste, including municipal solid waste (MSW), oil sludge, tires, plastics, organic waste, medical waste, agricultural waste, etc., both separately and in mixtures, excluding glass and metal.

- The reactor's temperature conditions can be adjusted within a range of 350° to 1150°, enabling low-temperature operation from 350° to 850° (for pyrolysis oil production) and high-temperature pyrolysis from 850° to 1150° (for heat and electricity generation).

- The ability to vary temperature settings allows for a quick transition between reactor operations for heat and electricity production (additional equipment such as gas turbine and gas piston units may be added to the price), or the production of pyrolysis oil in reverse.

- The equipment boasts unique ecological compatibility as it eliminates the need for exhaust gas pipes, and it accommodates a wide range of input raw materials. Additionally, it features an unparalleled system for obtaining light oil fractions (such as gasoline and diesel) from mixed waste to meet ecological and other requirements.

- The produced equipment can handle a daily recycling volume ranging from 10 to over 100,000 cubic meters (ca 5 tons – 42,500 tons), with the specific volume determined by the customer's needs.

- The pyrolysis oil produced has an exceptionally low sulfur level, contributing to reduced emissions of sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter, extending engine lifespan, improving fuel efficiency, reducing air pollution, ensuring regulatory compliance, and promoting sustainable shipping.

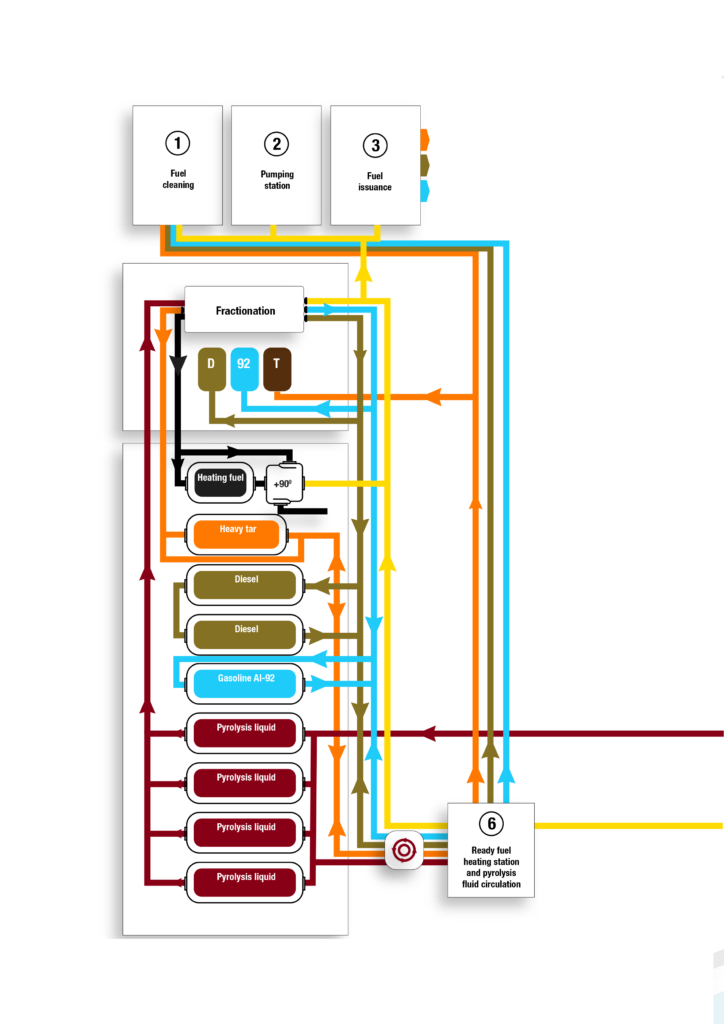

Basic scheme of our solutions:

1. Three-staged system of flue gas coming from the heater.

-

1st stage

The first stage of the system is mechanical, includes dry cyclone, which captured a large mechanical particles and scrubber with air-flow drip irrigation, what is washing out from the flue gas remaining after cyclone mechanical incorporation. -

2nd stage

The second stage is liquid. This wet scrubber, which circulates liquid absorbent recycled constantly flow a specific gas. This apparatus to remove acidic flue gas of the fragments. -

3rd stage

The third step provides maximum additional cleaning of flue gases, equipped with a dry filter-sink with bulk structure, allowing to completely absorb all harmful substances. These filters are used in air purification systems in nuclear shelters. Purified carbon dioxide enters the liquefaction in carbon dioxide.

2. Two-step purification of pyrolytic gas before its release

- Two-step purification of pyrolytic gas before its release to the gas piston power station and pyrolysis reactor. Ensures maximum cleaning of fuel gas, which in turn, prolongs life and reduces the amount of harmful emissions in its exhaust treatment facilities consist of bulk absorbers with by the recycled content.

3. Two-step Purification of Pyrolysis Liquid with Bulk Absorbers

- The two-stage purification of pyrolysis liquid is achieved by circulating heated pyrolysis liquid through bulk absorbers containing recycled material. This purification and filtration system ensures zero emission of gases and liquids into the environment.

Official results of tests conducted in Estonia in 2022.